The boil vessel is a 60 quart Vollrath pot. I purchased the pot

(and lid) from Something's Brewing, 196 Battery Street, Burlington,

Vermont 05401, (802) 660-9007, Somebrew@aol.com. I had P.B.S.

modify the Vollrath pot to include a ½" bottom drain.

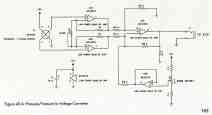

The boil vessel has a level indicator which is capable of measuring the volume of boiling wort. The level indicator design is based on a Motorola MPX2010GSX Pressure Sensor ($26) and a Motorola MC33079P Dual/Quad Operational Amplifier ($2). The actual circuit was taken from,

Bergsman, Paul, Controlling the World With Your PC (HighText Publications, Inc., Solana Beach, California, 1994). Tel. 1-800-247-6553

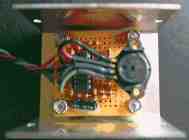

The boil vessel bottom drain has a ½" male-to-female elbow. I drilled and tapped a hole corresponding to a ¼"-20 stainless steel bolt into the top of the elbow. I drilled an 1/8" hole down the center of a ¼"-20 bolt. I filed the barb off of the pressure transducer and epoxied the pressure transducer to the bolt being careful not to get epoxy in the inlet port. A ¼"-20 nut secures the bolt and pressure transducer to the circuit board. A small rubber washer seals the project box to the stainless steel elbow. I am very happy with the form and function of the pressure transducer wort level indicator.

The pressure transducer is temperature-compensated, however, it operates well outside of its compensated range. This is due to its proximity to the boil propane stove. I use firmware to further compensate the pressure (wort) level. However, the problem here is that I don't have a temperature sensor in the boil vessel. I have to calibrate the wort level assuming a full boil.

I calibrated the firmware using quantities of boiling water (not wort). I repeatedly boiled water in one gallon increments and measured the output voltage of the pressure sensor to formulate a linear compensation.

If I replaced the boil propane stove with a 220 volt electric heater element, the pressure sensor would drop down more into its compensated range. And of course, the addition of a boil temperature sensor would allow for compensation through firmware which was adjusted based on the wort temperature.

Ideally, I would have used a stainless steel pressure transducer. All of the "wetted" parts are stainless steel. I looked at Applied Instruments P2000 stainless steel, amplified pressure transducer for $120. The P2000 is available with an operating range of 0 - 25 PSIG, an input voltage of 5 volts, an output voltage of 1 - 3 volts and a compensated temperature range of 30° F to 130° F (other ranges are available). The pressure port is 1/4" NPT.

The problem with stainless steel pressure transducers is that their pressure operating range is not small enough. If your water/wort were to generate 1 PSIG,

1 PSIG / 25 PSIG * 3 volts / 10 volts * 4096 levels = 49 levels where

which corresponds to the analog-to-digital "level" with the pot full of water/wort. If this is a 60 quart Vollrath pot, that is 49 levels / 60 quarts = 0.8 or less than one "level" per quart (i.e. the resolution of the water/wort level indicator will be worse than one quart).